Vision4ce Products

Video Target Tracking

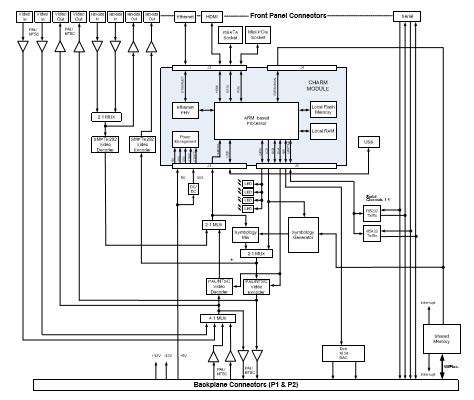

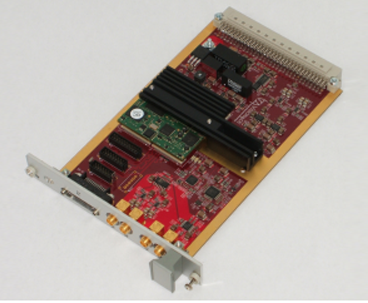

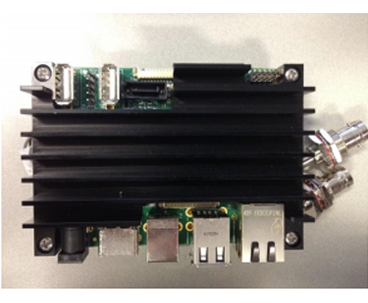

CHARM-6U VME

Video Tracker board 233.3 x 160mm (Double Eurocard)

The Vision4ce CHARM-6U VME video tracker uses the CHARM module and the DART (Detection & Acquisition, with Robust Tracking) detection and target tracking software hosted on an embedded multicore ARM processor board for video tracking and image processing applications.

If appropriate options are selected this board is a replacement for ADEPT 60 and ADEPT 36.

CHARM-6U VME

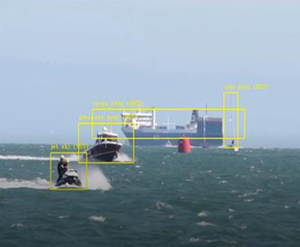

Video Detection & Tracking

A video tracker analyzes video image sequences from a sensor system (one or more cameras), mounted on a servo controlled pedestal (platform) to keep the camera pointing at the nominated person or object. In this context, a Tracker has two primary processing functions.

• Detecting and locating objects of interest in the video image (object location).

• Controlling the platform (Pan and Tilt) position and rate such that the camera follows the designated object (Pan and Tilt Control).

CHARM-6U VME Features:

Key Features

- • Multiple object detection and tracking

- • Centroid & edge measurement

- • Feature based correlation algorithm

- • Moving object detection

- • Adaptive background removal

- • Automatic coast

- • Grey level invariant algorithms

- • Robust clutter rejection

Standard Interfacing

- • Two analog video (NTSC, RS710, PAL or CCIR) inputs

- • Host interface through RS-232 or RS422 serial interfaces

- • Direct interface to sensors and Pan & Tilt platform through RS-232 or RS-422 serial interfaces

- • Two analogue video (NTSC, RS710, PAL or CCIR) video outputs with selectable symbology overlay

- • Buffered Video bypass for fault or test

Additional Image Processing Options

- • Electronic image stabilization

- • Image enhancement

Applications

- • Security and surveillance

- • UAV & UGV

- • Manned vehicles

CHARM-6U VME Options and Applications

The CHARM 6U is a high-performance video tracker that meets the mechanical requirements of a conduction cooled double height Eurocard (DIN41494).

Interfaces (Standard)

• Two analogue video inputs

– 1.0V peak to peak into 75 Ohm

– CCIR, RS170, PAL or NTSC

• Two analogue video outputs

– 1.0V peak to peak into 75 Ohm

– CCIR, RS170, PAL or NTSC (depending on input)

– Selectable symbology overlay

– Optional conformal coating available

• Two bidirectional serial interfaces

– RS232 or RS422

– Asynchronous

– Baud rate variable up to 115,200

• Gigabit Ethernet

Additional video Interfaces (Optional)

• Two HD-SDI video inputs

– 1920x1080i60/50, 1920x1080p30/35, 1280x720p60/50, 720x480i30, 720x576i25

• Two HD-SDI video outputs with 5-pixel latency

• VMEbus (ADEPT 60 Protocol)

Connectors

• 1x 25 way Micro ‘D’ Plug

– 2x serial interfaces

• 4x SMA Jacks

– 2x video inputs

– 2x video outputs

• RJ45 Socket

• 96way DIN 41612 Type C

– 2x serial interfaces

– 2x video inputs

– 2x video outputs

– USB 2.0

– Power +5VDC

• 96way DIN 41612 Type C for VME

Power

• +5V, < 12 watts

Mechanical

The CHARM 6U conforms to the 19” rack specification (DIN 41494) as a double Eurocard PCB module (6U x 4HP).

Environmental

• Copper side strips provide surfaces for conduction cooling via wedge locks.

• Temperature

– Operating -40C to +70C

– Non-operating -55C to +95C

– Thermal shock (operating) > +/- 5C per minute

• Humidity

– 5% to 95% non-condensing

– Optional conformal coating available

Designed and Manufactured in the UK.